Instructions

Please Read

Disclaimer

I used a dremel with 3 different bits plus some 400 grit

sand paper for this project. I know why gunsmiths charge a lot for

this stuff, it takes a bit of work to get this done. If you plan on

changing your sear I would install the new sear first, then perform the

trigger job.

1. Field strip your gun. (Instructions)

2. Disassemble the trigger assembly. (Instructions)

3. Remove the over travel screw out of the new trigger.

4. Check that the trigger pivot pin fits into the bottom

horizontal hole on the new trigger. If the pin fits, skip to step

7. If it does not you will need to widen it.

5. Using the routing bit (above picture, the bit on the

right) widen the hole. Check every 10 or so seconds to see if it is

wide enough. Be careful not to tilt the bit and wallow

out the hole but to keep it straight and widen

it.

6. You are done with this when the trigger will spin

around the center of the pin freely (gun oil will help test the fit).

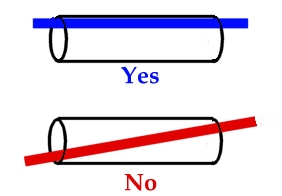

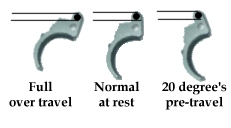

7. Test that the trigger's top horizontal hole will fit

onto the end of the disconnector assembly and can pivot smoothly from full

trigger over travel (trigger hits the disconnector assembly) to about 20

degrees pre-travel. If it is smooth already go to step 9. If

it does not you will need to widen it.

8. The hole goes from wide to narrow and it's the top wide

part that needs to be widened. Keep repeating step 7 and 8 until it

is smooth.

9. Insert trigger into grip with all parts in place except

the over travel screw.

10. To check pre-travel pull the trigger slowly. You

should see the trigger and disconnector assembly move but not move the

sear when you start to pull the trigger. You can also feel the

difference in the trigger pull, pre-travel is only the trigger spring

weight and sear movement will increase the resistance on the trigger from

the sear spring. If the sear moves no matter what and/or you don't

feel 2 different pull weights, remove the trigger from the grip.

11. Grind, file, or sand off the bottom of the trigger

where it touches the trigger guard about 1/32 inch. Reinsert trigger

into grip and repeat step 10 until you feel 2 different pull weights.

12. Once you feel the first lighter pull weight, the

pre-travel distance you have to pull is up to how much more you want to

remove from the end of the trigger. On my trigger the pre-travel

cleared at 1/32in grind but I removed another 1/16in more to keep from

having such a hair trigger.

13. Once pre-travel is adjusted, remove the trigger

and apply cold blue solution to the newly sanded/filed parts. Then insert the over travel screw and reinstall trigger and trigger shield

(if you made one).

14. To keep from dry firing my gun too many times I

roughly adjusted the over travel by pushing on the hammer and pulling the

trigger at the same time. Adjust the over travel screw to touch the

frame just after the hammer is released.

15. Assemble gun.

16. Dry fire the gun, but pull the trigger slowly to

feel the distance between the "click" and the frame.

Adjust over travel screw to personal comfort. Use Blue

Locktite to keep the screw from moving after repeated firing.